DfM Analysis

Design-for-Manufacturing (DfM) is the process of qualifying if a PCB is manufacturable, both in terms of fabrication and assembly.

DfM involves addressing manufacturing requirements prior to fabrication, to verify if the design aligns with a manufacturer’s process capabilities.

The list of possible design flaws that can compromise quality is long, necessitating a comprehensive DfM analysis that includes a substantial number of rule checks, categorized as follows:

- Checks of footprints against verified components

- Checks of clearances against process capabilities for components, traces, via, solder mask, stencils, etc.

- Checks against specific industry requirements, for example IPC, IEC and MIL-STD standards

These manufacturing requirements ultimately translate back in the design guideline, highlighting the significance of comprehensive error reporting, to facilitate efficient communication between board designers and manufacturers.

Comprehensive DfM solution

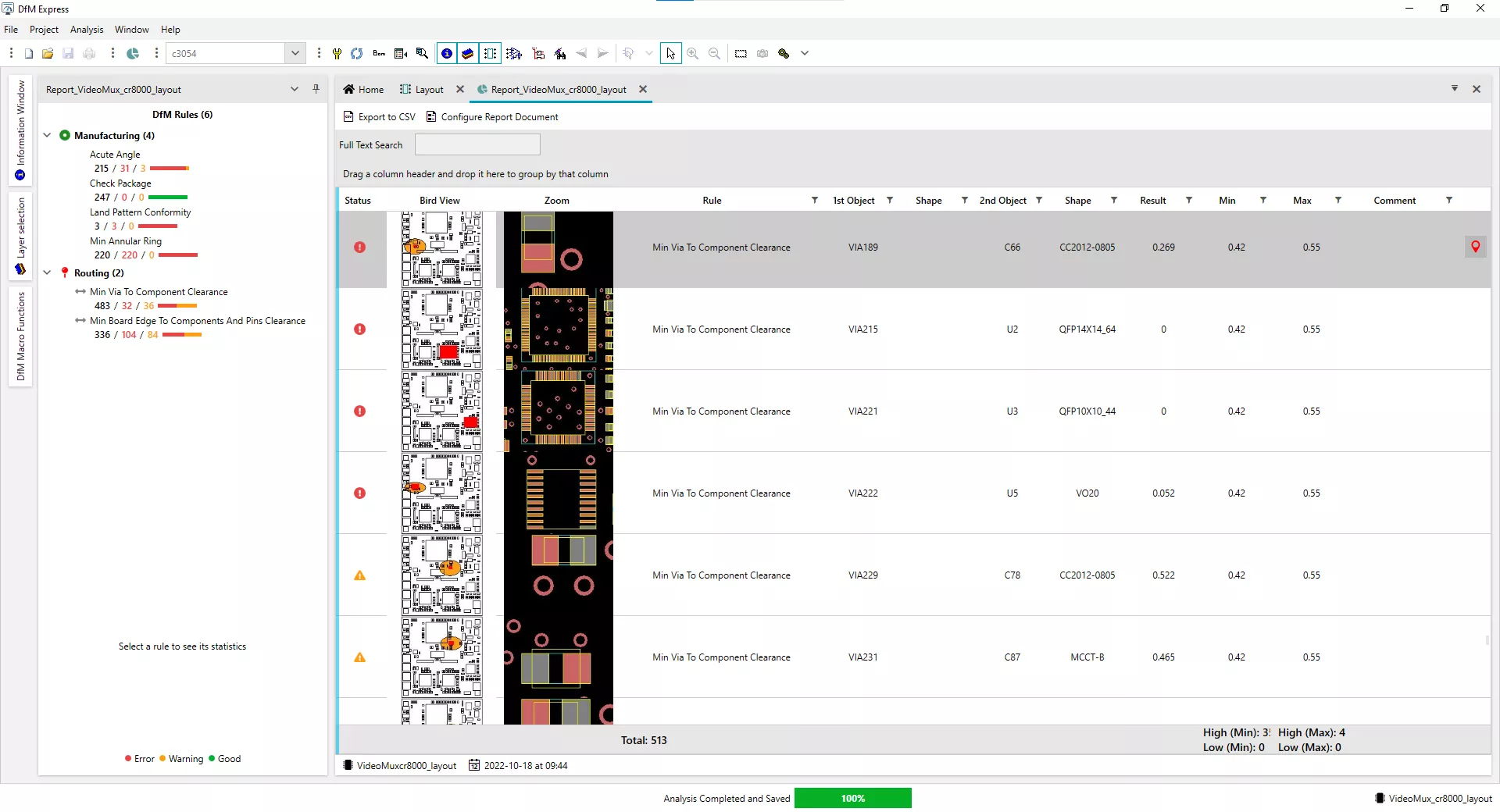

Verifying manufacturing requirements often requires the creation of hundreds to thousands of checks. This can pose challenges in sifting through the large quantity of results to find meaningful information.

ASTER has developed a simple, intuitive DfM solution to facilitate the configuration and programming of rules, as well as the communication of analysis results.

- Visual graphical interface: An intuitive GUI allows for the configuration of DfM analysis profiles, by simply dragging & dropping pre-defined rules, setting filters and thresholds

- Rules programmability: A low-code interface simplifies the programming of thousands of checks, to automate the verification of design guidelines

- Reporting configurability: An embedded reporting engine allows the configuration and generation of Word, Excel, PowerPoint and Adobe PDF documents

DfM analysis profile

ASTER’s solution enables users to create Design Rules Checks (DRC), Design-for-Manufacturability (DfM) and Design-for-Assembly (DfA) analysis profiles using pre-defined and custom rules.

- Import layout data such as ODB++, IPC-2581, GENCAD, FATF, or direct from native CAD layout data

- Use pre-configured DfM checks such as IPC standards and adapt thresholds to local manufacturer constraints

- Create custom rules using a low-code interface to automate the verification of custom design guidelines

Cockpit visualization environment

ASTER’s solution enables navigating through the cockpit to review, sort, classify and comment on the violations. It offers full interactivity with the layout view and utilizes advanced filtering options to display errors effectively.

- Cross-probing between layout and reports

- Use standard templates to generate Word, Excel, PowerPoint and PDF reports

- Customize the report structure with Report Designer, to fit with your corporate requirements