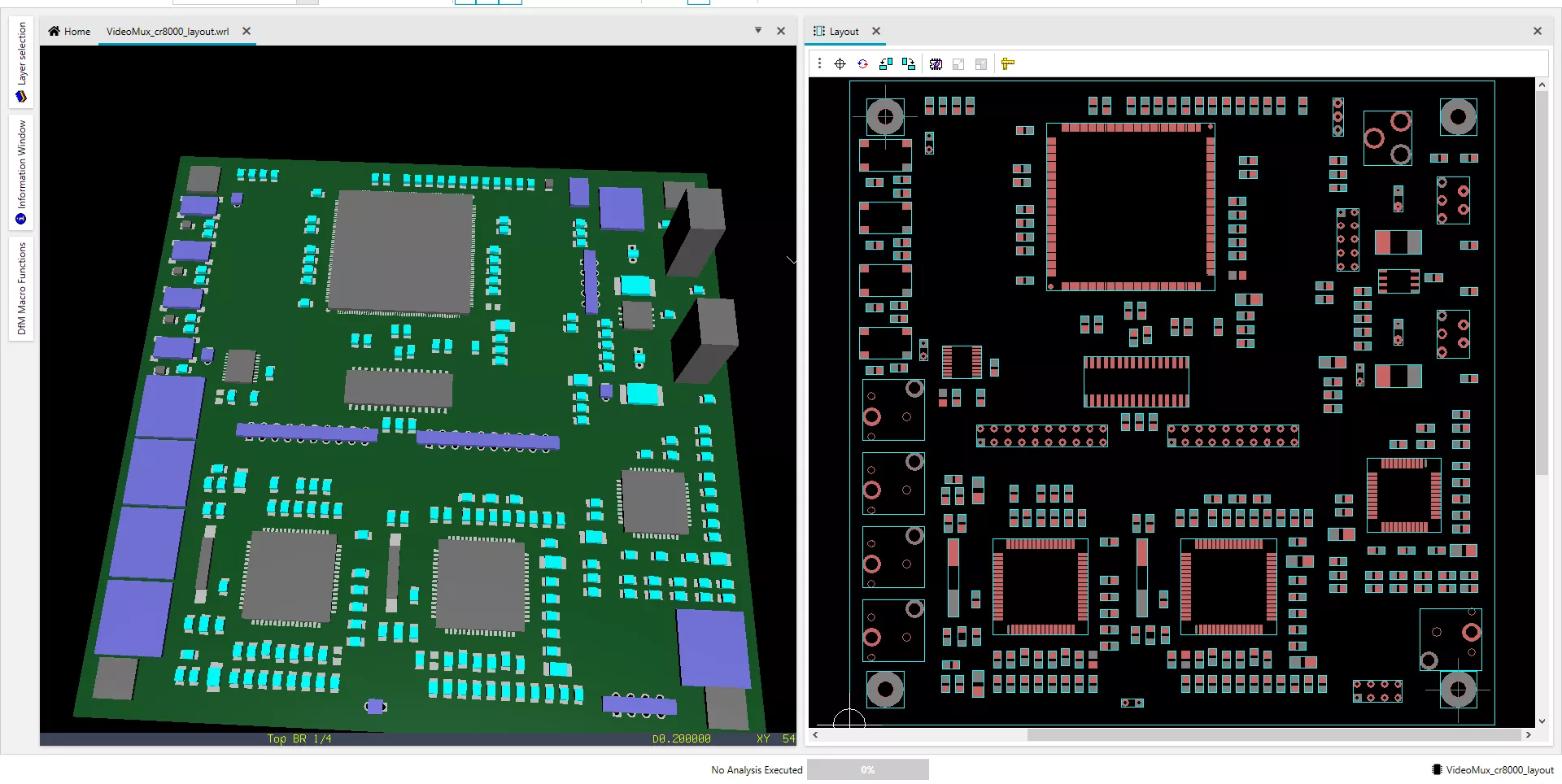

DfM analysis tool

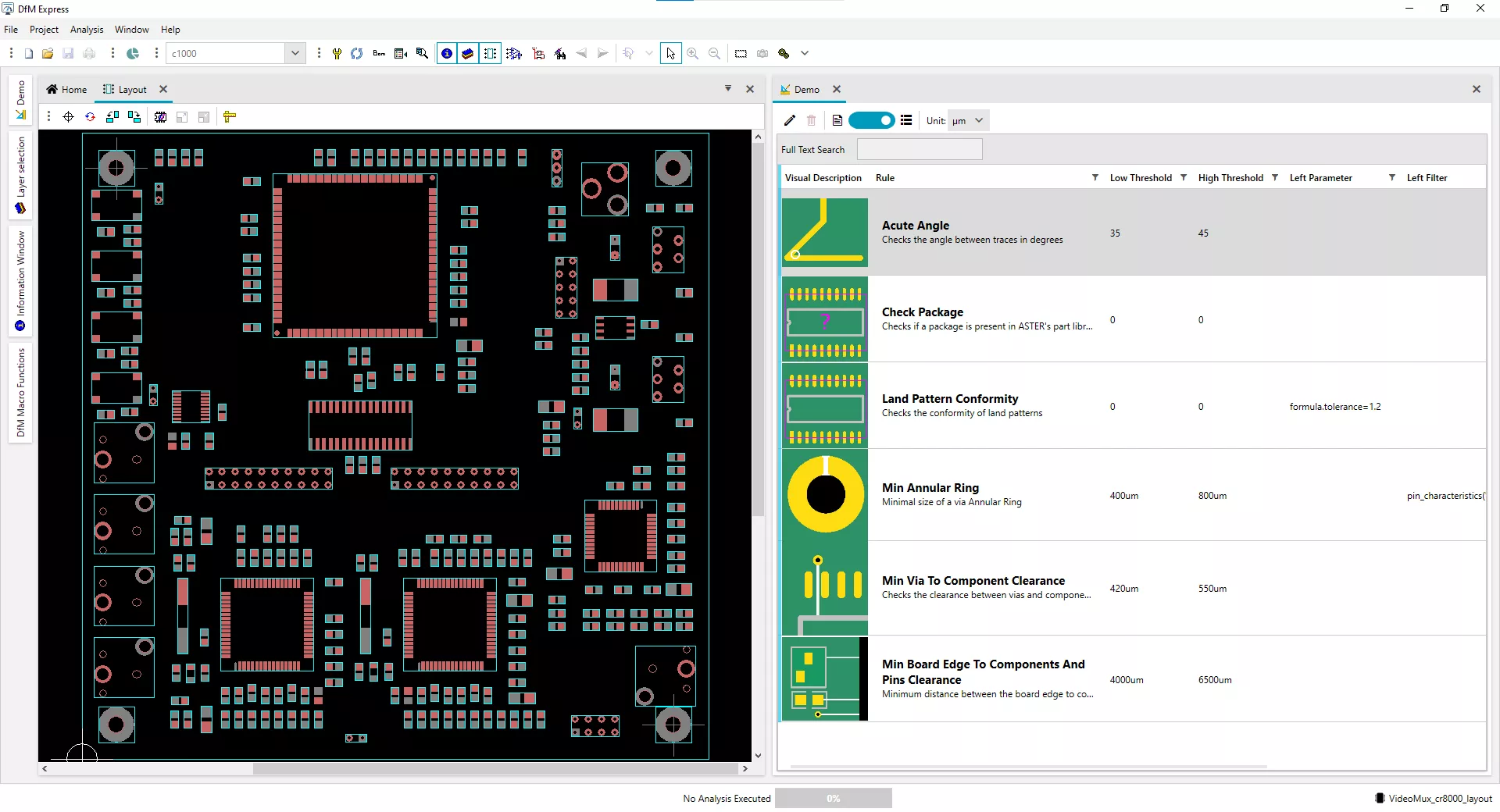

DfMExpress allows the configuration of Design Rules Checks (DRC), Design-for-Manufacturability (DfM), and Design-for-Assembly (DfA) analysis profiles by simply dragging & dropping pre-defined rules, setting filters and thresholds.

Users can lean on pre-configured industry checks such as IPC standards, and adapt thresholds to local manufacturer constraints.

Additionally, a low-code interface simplifies the programming of thousands of checks, to automate the verification of design guidelines.

V. Leboeuf

Dassault Aviation

They trust us to deliver the best value for their software investment

Fully integrated DfM software

The visual graphical interface makes it easy to configure and program rules and reports on analysis results.

- Import layout data such as ODB++, IPC-2581, GENCAD, FATF, or direct from native CAD layout data

- Use pre-configured DfM checks such as IPC standards and adapt thresholds to local manufacturer constraints

- Create custom rules using low-code interface to automate the verification of your design guidelines

- Navigate through the cockpit visualization environment, to review, sort, classify and comment on any violations

- Use standard templates to generate Word, Excel, PowerPoint and PDF reports

- Customize the report structure with Report Designer, to fit with corporate requirements

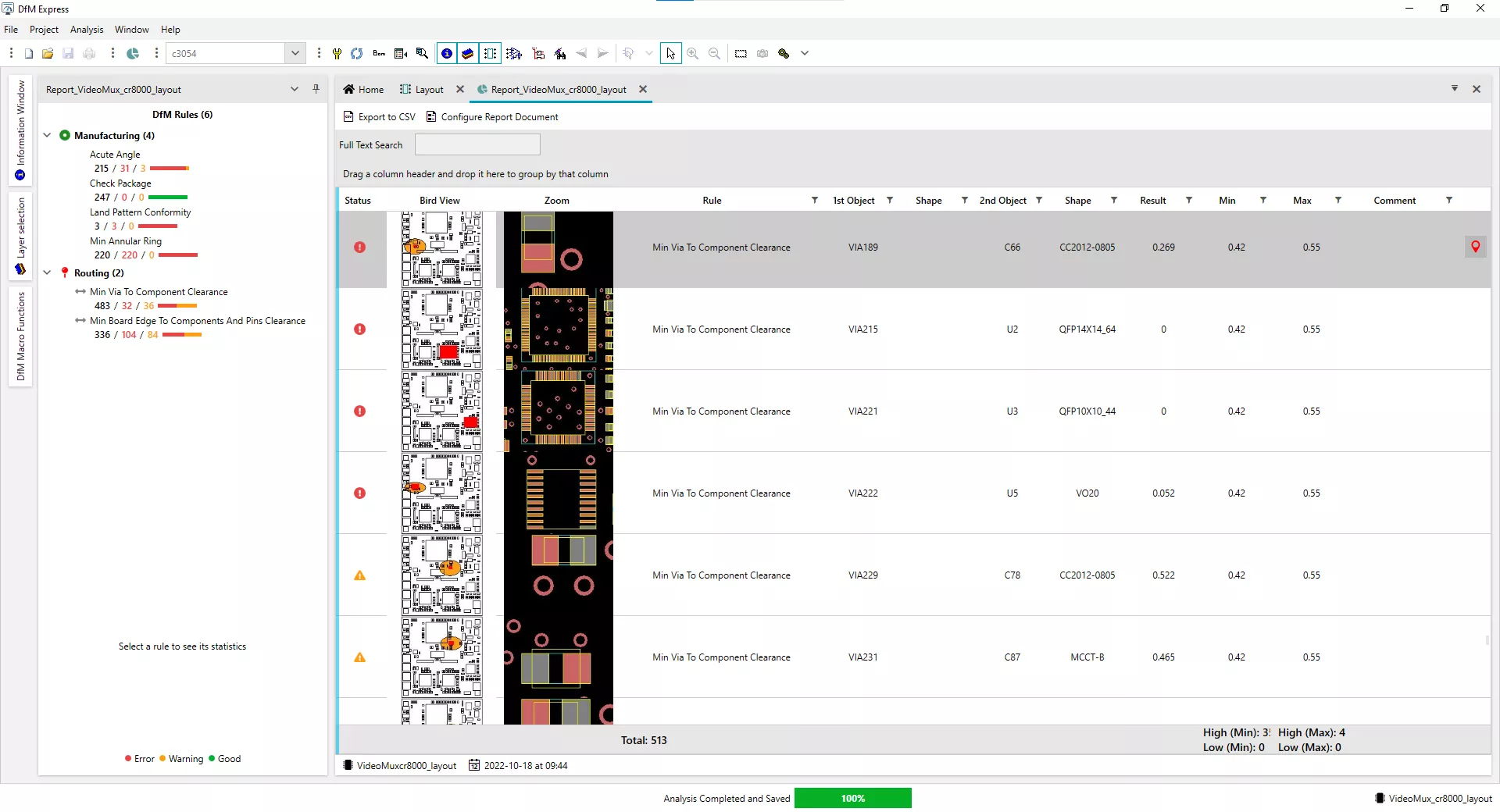

Cockpit visualization environment

The cockpit provides a graphical environment to visualize the analysis results. It offers full interactivity with the layout view. Navigating through the cockpit, users can review, sort, classify and comment on any violations.

- Utilize advanced filtering options to display errors effectively

- Cross-probe between cockpit and layout view

- Use standard templates to generate Word, Excel, PowerPoint and PDF reports

Advanced reporting

DfMExpress analysis data can be exported in a variety of formats such as Word, Excel, PowerPoint or Adobe PDF.

The report structure is defined by a template, which could be easily edited with the free Standalone Report Designer, to fit with your corporate requirements.

Download Product Brief

Why ASTER Technologies ?

We offer comprehensive software tools to simulate a PCBA and the manufacturing/test machines in a digital environment. Digital twin technology allows our customers to ensure PCBA fabrication and improve test coverage, to limit the risk of undetected defects, thereby reducing field failures and costly recalls.