Machine programming software

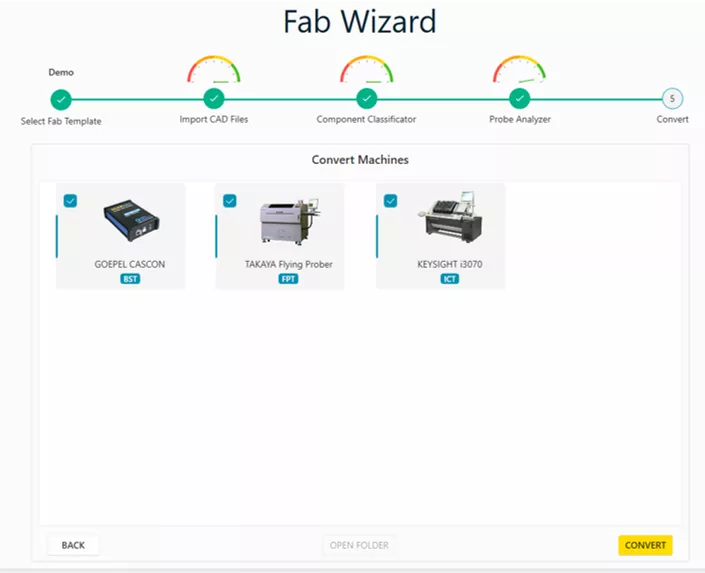

The intuitive graphical user interface provides a step-by-step wizard that directs users through a 5-stage process:

- Select production machines

- Import CAD data

- Modelize components

- Place the probes

- Generate output files

FabExpress imports from any CAD formats. It embeds a layout viewer, and ASTER’s Probe Analyzer solution to automate probe placement for fixture and fixture-less test systems.

The software offers output processors for programming SPI, Pick-&-Place, Chip shooter, AOI, X-Ray, Boundary-scan, Flying Probe and In-circuit testers.

FabExpress generates standard formats such as Centroid, Gerber, Fabmaster, XML and proprietary formats for all brands of equipment. It also creates reports for bed of nails, including Excellon and DXF files.

T. Dolley

Manager at Robert Bosch Automotive Electronics

They trust us to deliver the best value for their software investment

FabExpress Software Packages

For programming of Assembly, Inspection (SPI, AOI, X-Ray), In-circuit & Flying probe

Features

- CAD importers

- Layout viewer

- Probe Placement

- Programming of ICT and Flying probe testers

- Programming of Boundary-scan testers

- Programming of Pick & Place, Chip shooter

- Programming of SPI, AOI, and X-Ray machines

- FATF exporter

Programming the entire shop floor

The FabExpress program generation software offers output processors for programming production machines: SPI, Pick-&-Place, Chip Shooter, AOI, X-Ray, Boundary-scan test (BST), Flying probe test (FPT) and In-circuit test (ICT).

- Direct conversion from any layout format including GENCAD, CAMCAD, FATF, ODB++

- Automate probe placement based on design, test parameters and mechanical constraints

- Output proprietary file formats for all brands of equipment

- Generate Centroid, Gerber, Fabmaster and XML files

- Create reports for bed of nails, including Excellon & DXF files

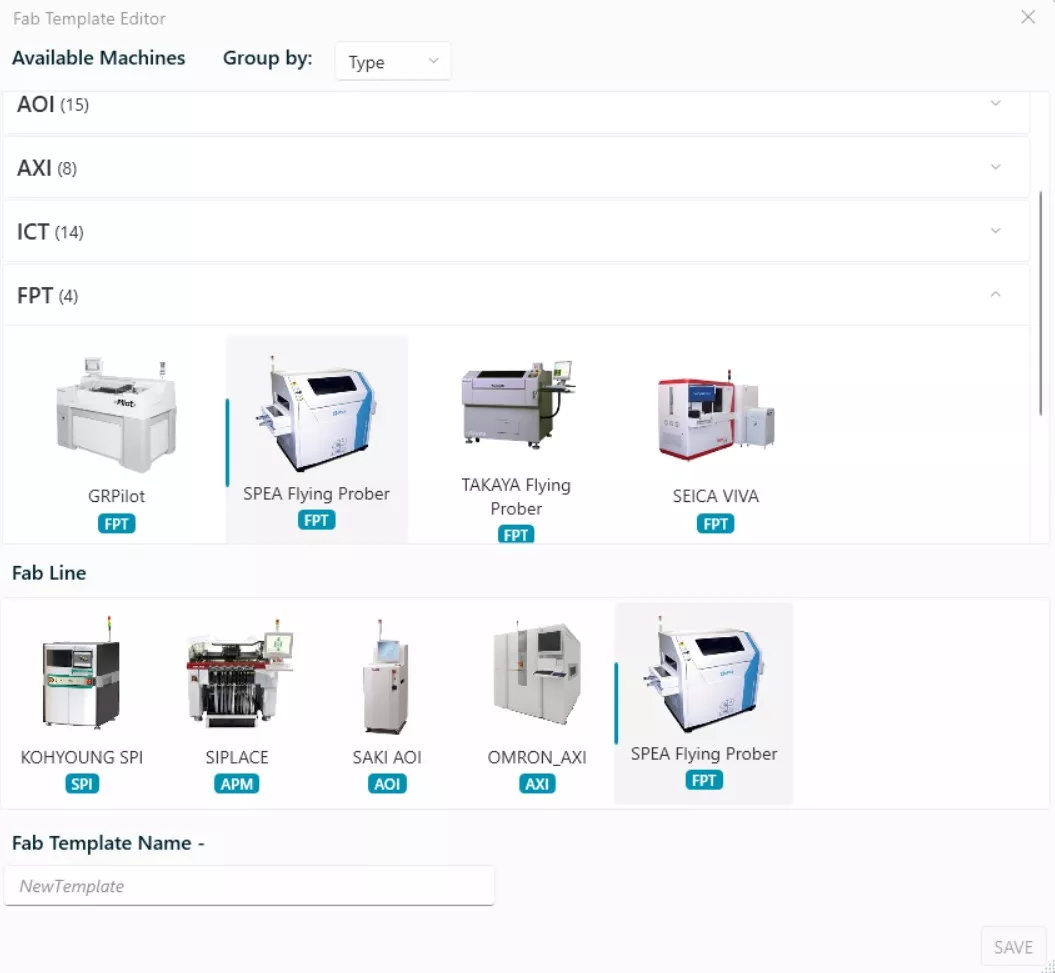

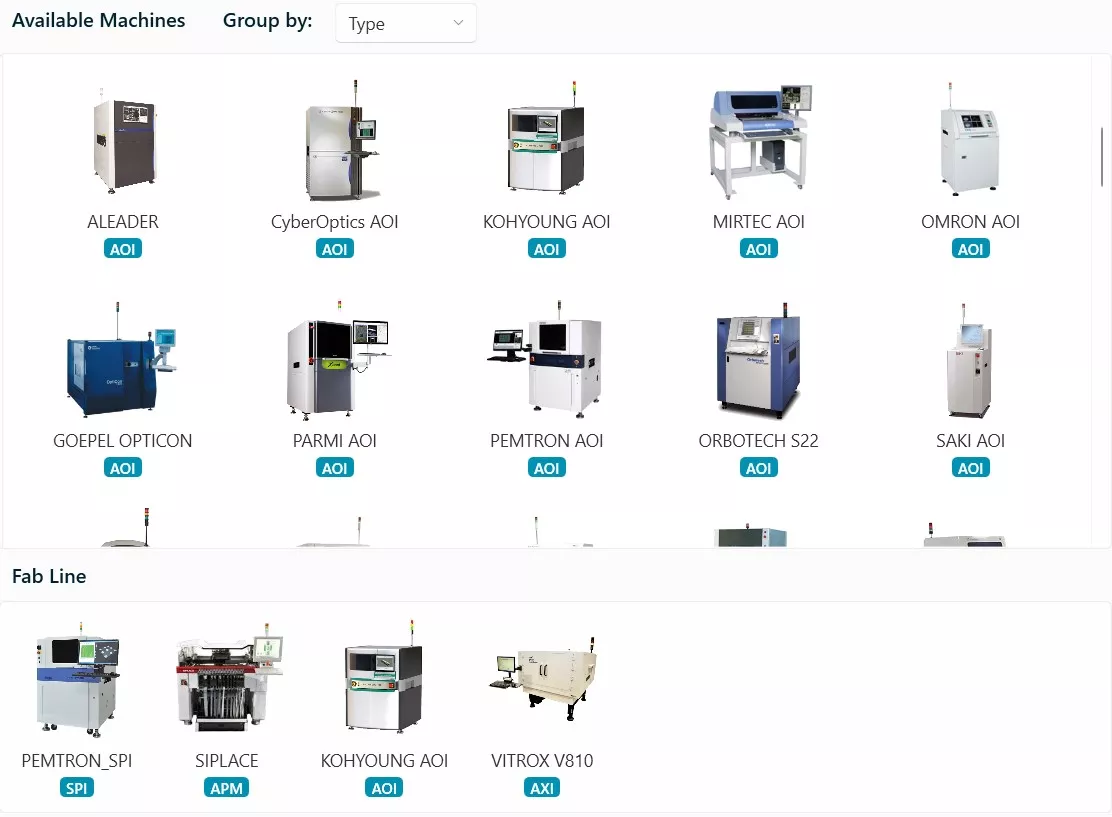

Select production machines

The graphical user interface (GUI) allows users to browse through the different equipment categories and simply drag and drop their selection to create their “fab line profile”.

The profile can comprise of a single system or multiple assembly, test and inspection machines, allowing simultaneous CAD-to-CAM translation.

The various profiles are saved in a fab template, enabling output files with the same configuration to be generated for multiple projects.

- Support for Assembly, SPI, AOI and X-Ray systems

- Boundary-scan, In-circuit and Flying probe testers

- Comprehensive GUI for configuration of each machine, defined in the profile

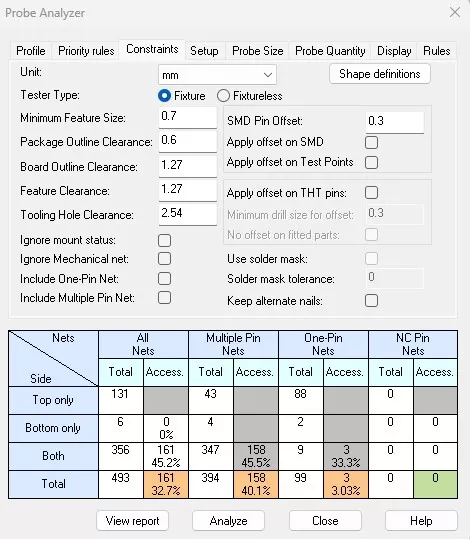

Probe placement

ASTER’s Probe Analyzer solution allows users to place probes for both fixture and fixture-less systems. It incorporates innovative algorithms to:

- Automate probe placement based on design and test parameters

- Check clearances to confirm test access is not compromised by mechanical constraints

- Simulate virtual probes to optimize arrangement for maximizing coverage

Output files generation

FabExpress translates CAD files into assembly and testing instructions to program Pick-&-Place, Chip Shooter, SPI, AOI, X-Ray, Boundary-scan, In-circuit and Flying probe machines.

The software allows users to configure output processors according to the system’s capabilities and to export output files using their format preferences.

- Generate Centroid, Gerber, Fabmaster and XML files

- Create Fabmaster and proprietary file formats for all brands of equipment

- Generate reports for bed of nails, including Excellon & DXF files

Why ASTER Technologies ?

We offer comprehensive software tools to simulate a PCBA and the manufacturing/test machines in a digital environment. Digital twin technology allows our customers to ensure PCBA fabrication and improve test coverage, to limit the risk of undetected defects, thereby reducing field failures and costly recalls.