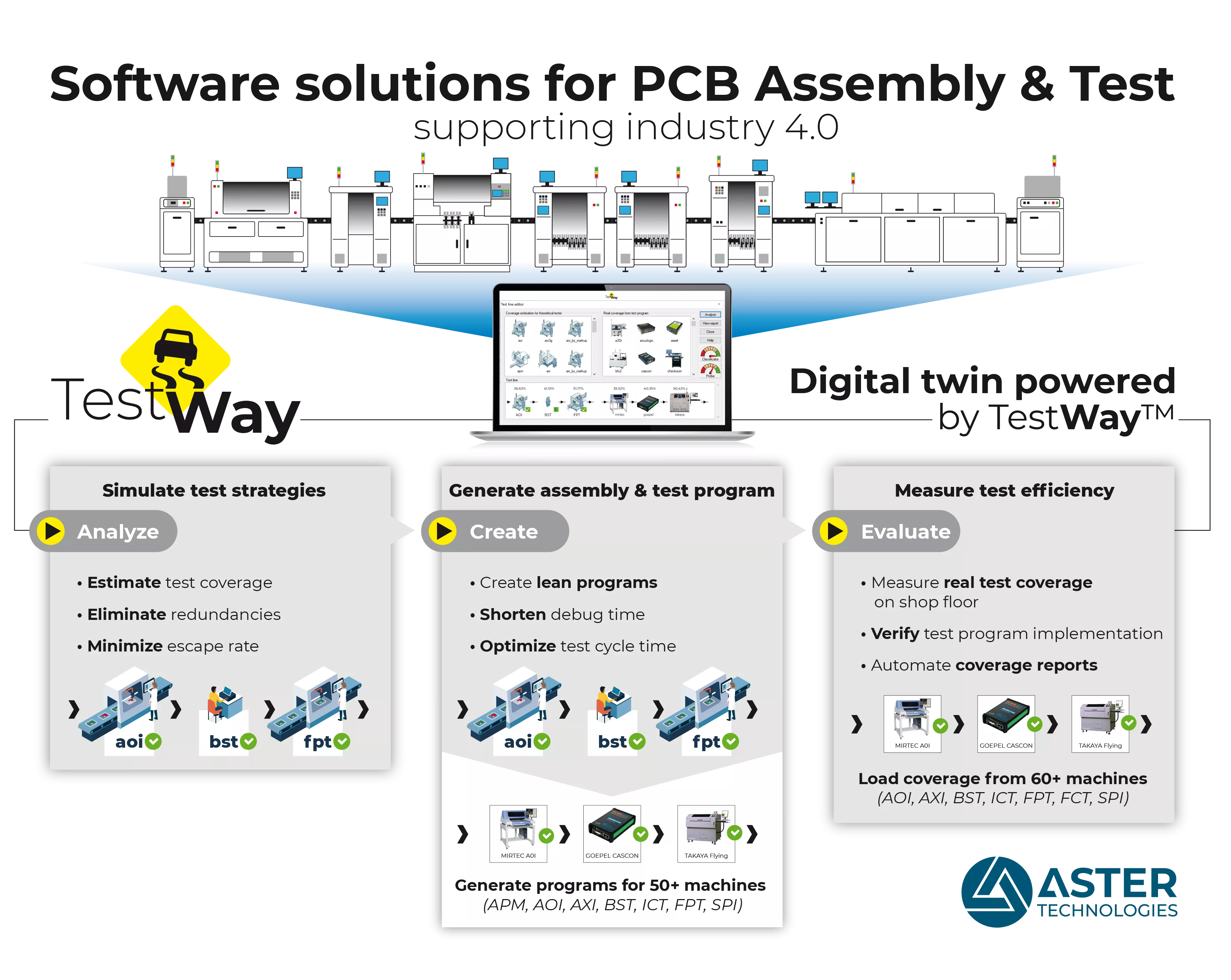

Technologies

Digital twin

Faster prototyping, testing and validation of products and processes

Digital twin for the electronics industry

Digital twin technology creates a virtual copy of a physical object or system. The ASTER software platform creates the digital twin of:

- Printed Circuit Board Assembly (PCBA) from layout, schematic and netlist files

- Component placement machines including pick & place and chip shooter

- Inspection equipment including Solder Paster Inspection (SPI), Automated Optical Inspection (AOI) and Automated X-Ray Inspection

- Electrical testers including Boundary-scan, In-circuit and Flying probe

ASTER's software solutions allow engineers to simulate PCBA and the manufacturing/test machines in a digital environment to:

- Analyze designs for potential failures and defects: By using DRC, DfM, DfA, DfT, companies can prevent defects and optimize the design of electronic systems before they are built

- Simulate test strategies to maximize test coverage: By simulating different tester methods, companies can maximize defect detection to push failures upstream of production operations

- Generate lean test programs to optimize efficiency: Test strategy simulations eliminate test redundancy, optimizing cycle time, reducing debug time and saving engineering time

They trust us to deliver the best value for their software investment

Digital twin benefits

- Faster time-to-market: Digital twins enable faster prototyping, testing and validation of products and processes, reducing development costs and risks

- Improved quality and reliability: Digital twins can simulate various scenarios to ensure optimal functionality and also allow for rapid iteration and feedback loops, enabling continuous improvement and innovation

- Enhanced customer satisfaction: Digital twins can provide users with personalized and interactive experiences, such as customized features